Cutting-edge Products

Scroll down to learn more

FLOATING OFFSHORE WIND POWER

A floating offshore wind turbine is a type of offshore wind turbine that is installed on a floating structure floating on the sea. The floating structure is made of concrete or steel and is designed to be anchored to the seabed with mooring ropes to prevent it from drifting. Our company has been conducting researches and developments on floating offshore wind turbines, and has already carried out actual demonstrations by using the whole real working set of this system.

The overall structure of our "floating offshore wind power generation system" consists of the three different systems as follows

Wind power generation units 5MW/6MW/8MW/10MW unit

Floating platform

Consists of three cylindrical main floating bodies connected together in a frame structure. The main unit consists of a float, ballast tanks and balance boards.

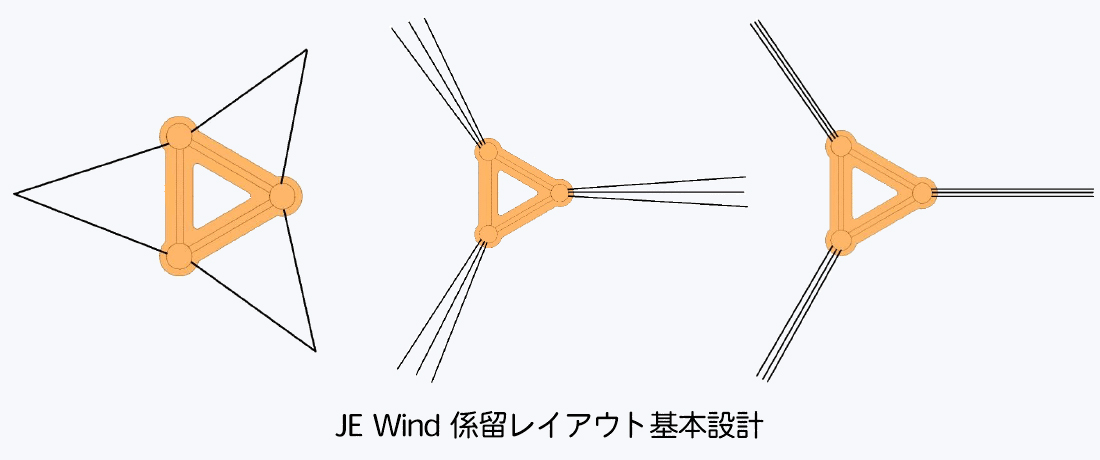

Mooring system

The weight is installed vertically on the mooring cable to increase the tension of the cable and it increases the rigidity of the floating structure.

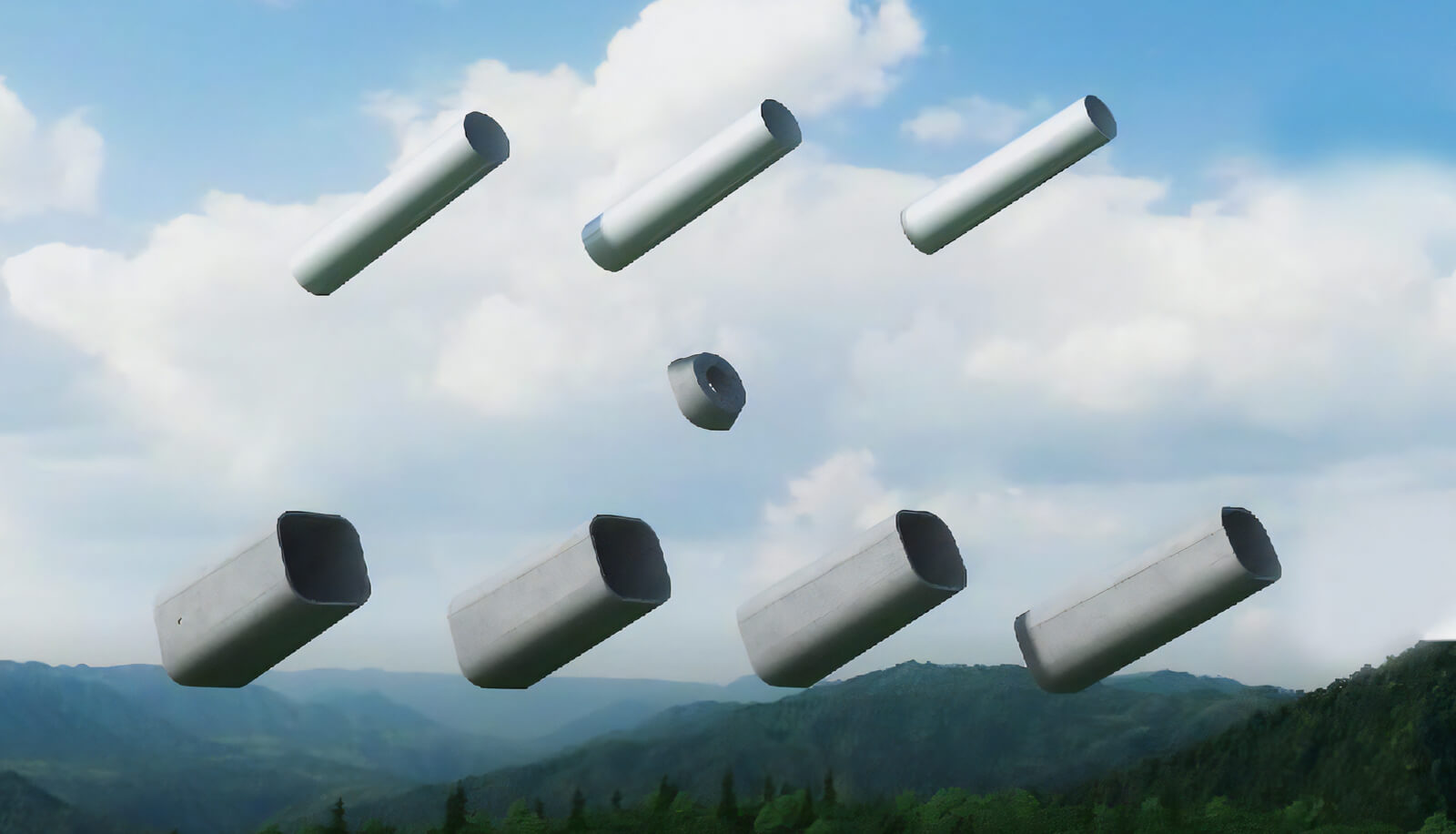

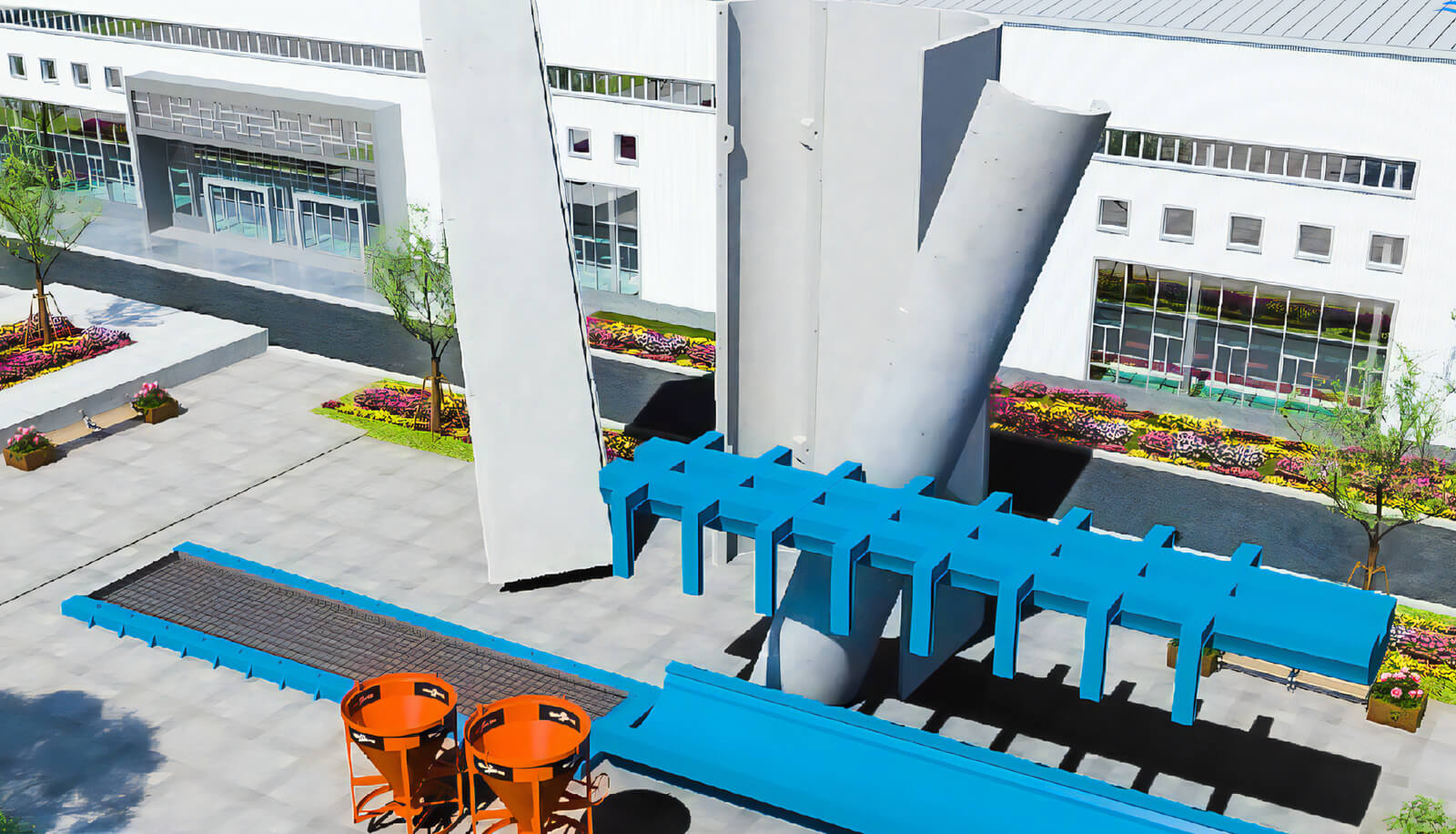

CONCRETE TOWERS

We have designed and developed a new type of concrete tower in "slicing" form as a windmill tower to make it suit the unique Japan-specific environments. With the advent of the “slicing ” format, our windmill towers can be easily installed in any location, which in turn can maximize your revenue. Our newly-designed "slicing" form concrete is modularized so that any other companies' concrete wind turbines can be mounted on it.

Reliable Design Technologies

- Our concrete towers are made of steel mixture concrete that are durable and will not easily deform, which is a high-reliable designing.

- technology to assure stable power-generating operations for you.

Advanced Production Technologies

- We make our concrete towers by using only a few different type of molds, which means that we can make those concrete towers accurately and furthermore the towers can maintain their high-quality through installation processes. This is a realization of high production technologies.

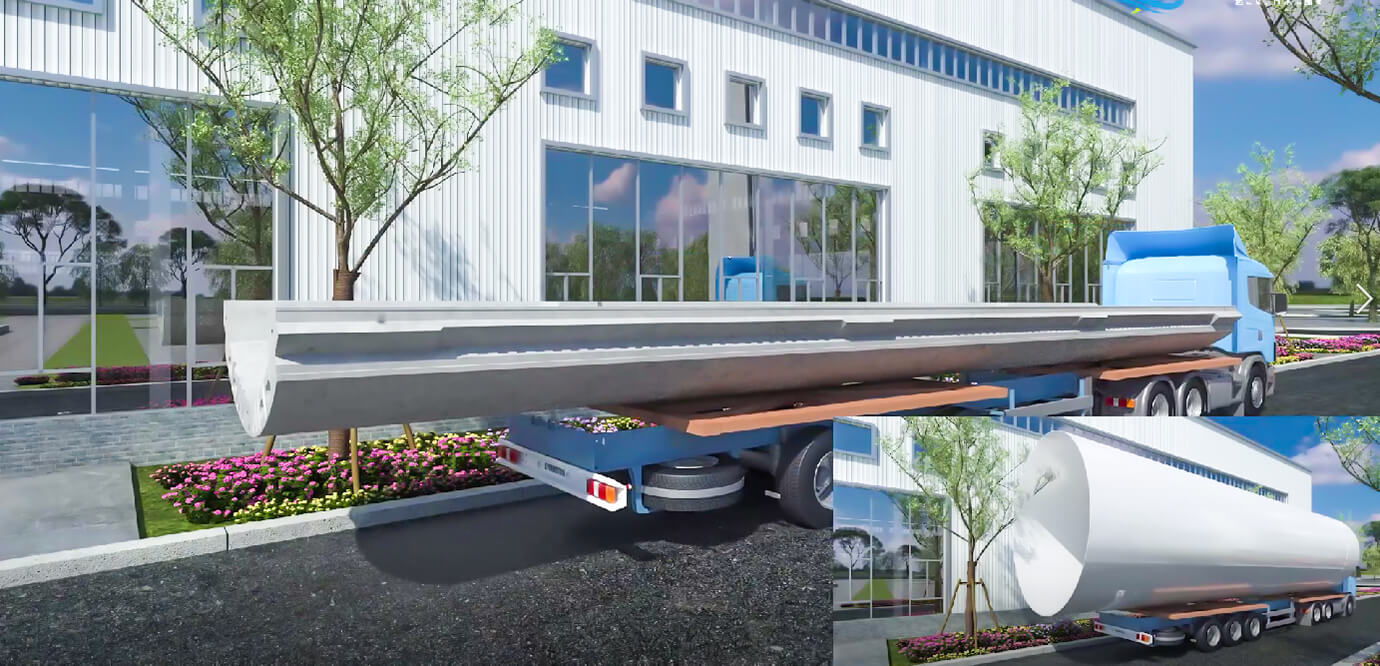

Transportation, installation and maintenance

- transport

Slicing concrete towers meet unique Japan-specific requirements for land transportation and its means that no excessively large-sized trucks are not needed. - Installation

The number of slicing concrete towers actually installed around the world is 1500. It has eliminated the needs for any large or specialized equipment for installation, and as a result it ensures accuracy through installation processes and provides efficient and low-cost operation. - Repair and Maintenance

Steel mixtured towers reduce maintenance costs. In addition, each of those towers has a large empty space in it for a safe maintenance work.

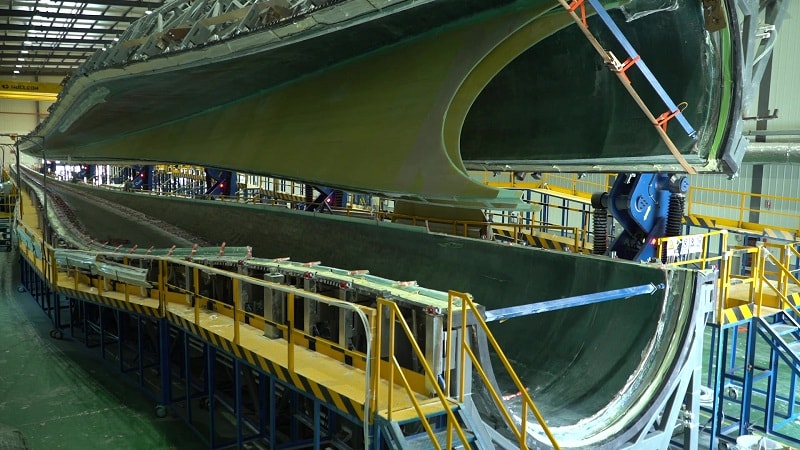

CARBON FIBER BLADE

The weight of each blade has been reduced from 32 tons to 25 tons.

The above-said lighter weight reduces the burden on the hub, allowing longer blade windmills to be designed.

It becomes easier to install the blades of the same length (thanks to the above-said lighter weight, which as a result helps to reduce construction costs.

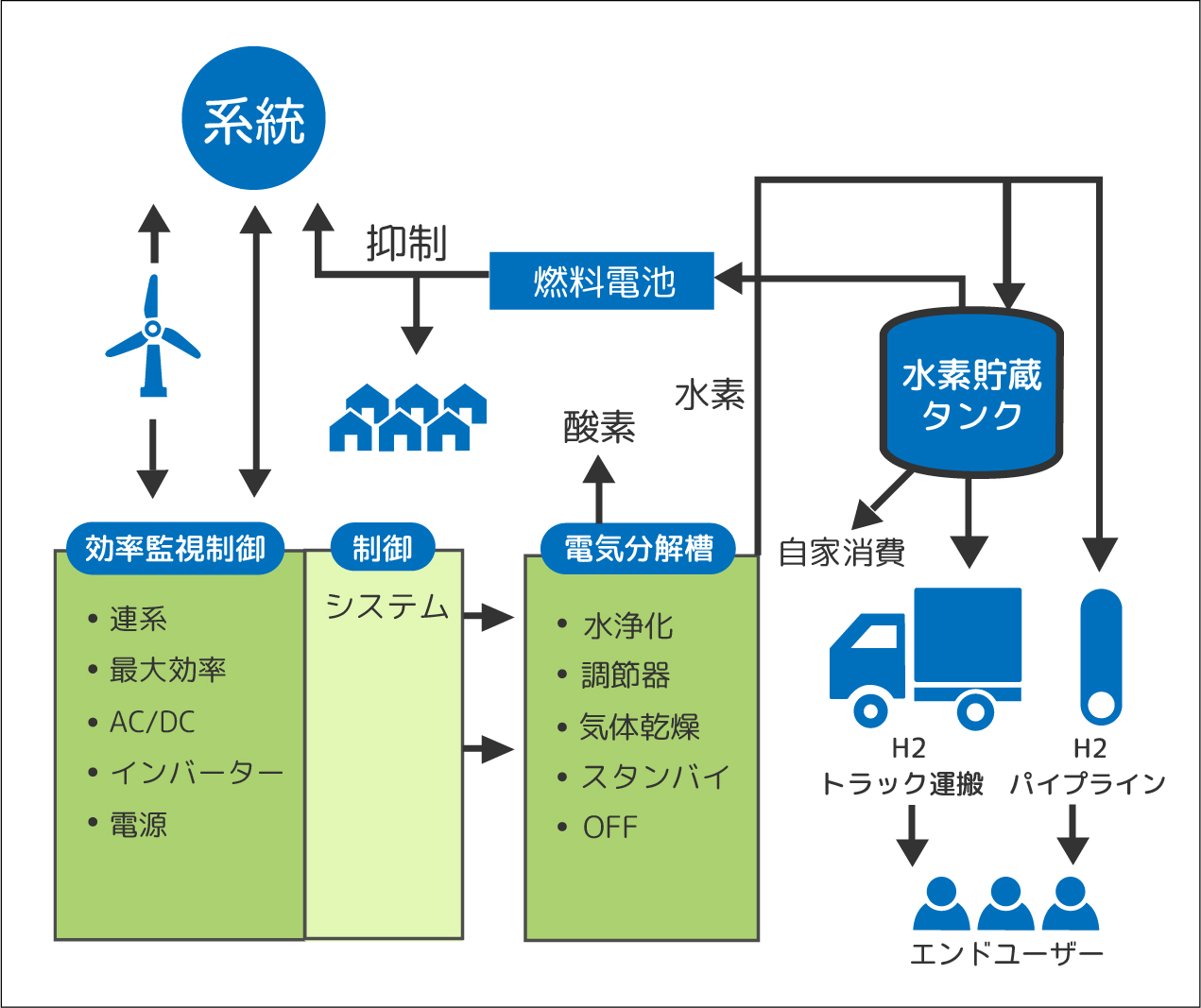

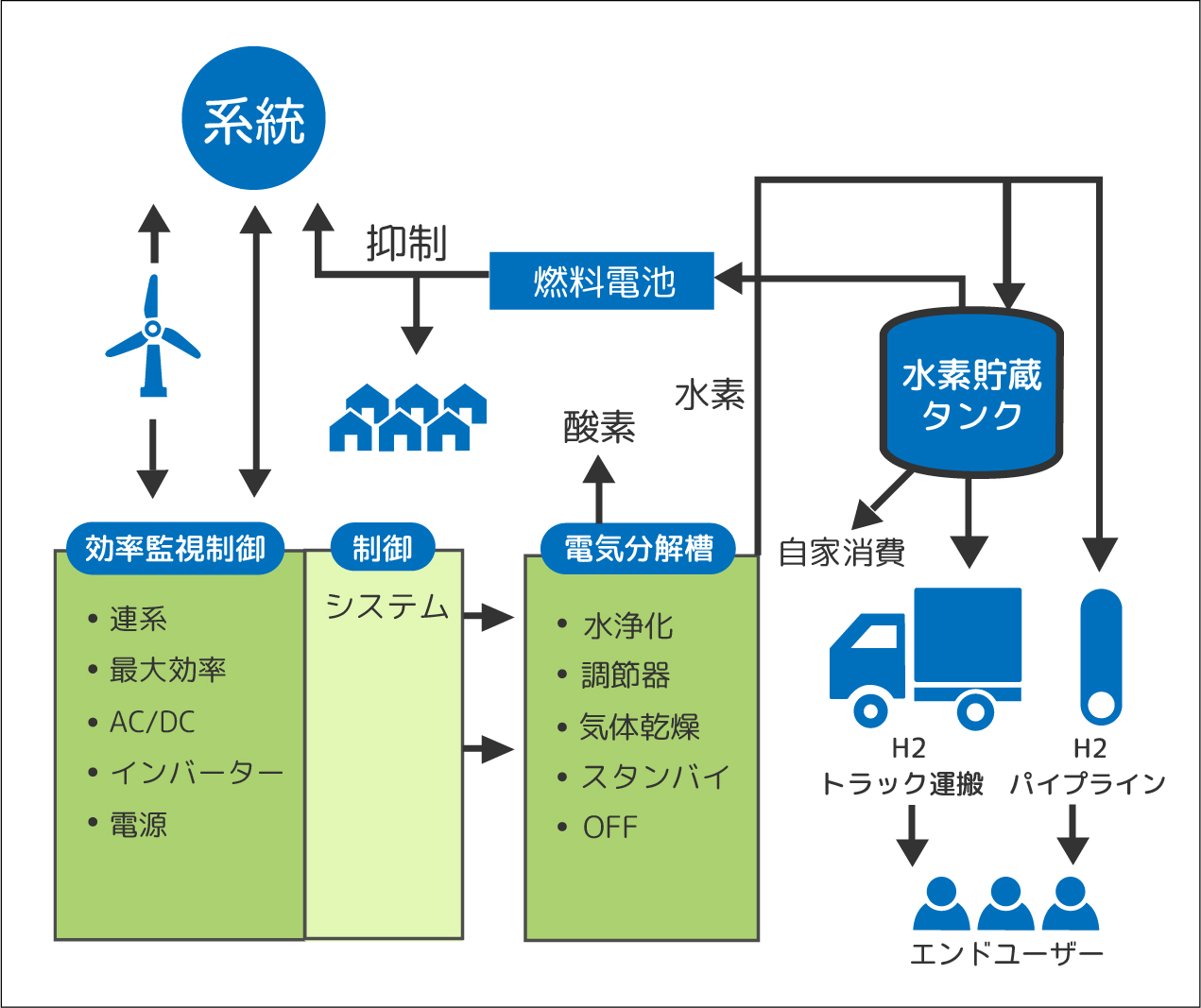

H2 (Hydrogen)

JE Wind supports the "Power to Gas (hydrogen)" enterprises.

We will contribute to the hydrogen society by designing and constructing the entire system as shown in the figure based on the actual situation at the given sites.